Voltage: 1/220KV

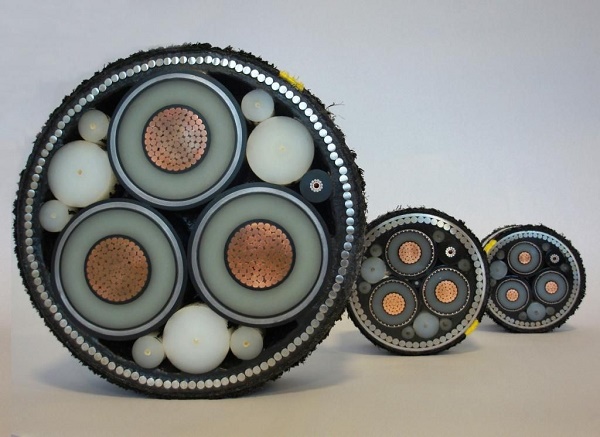

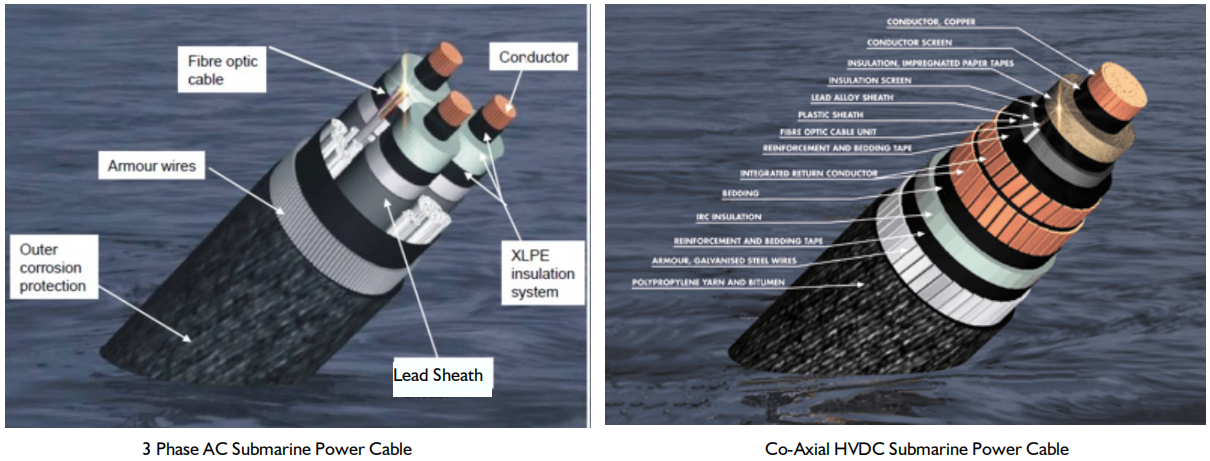

Core: Single or Three

Conductor: Copper conductor, circular stranded compacted, water blocked,

Conductor Screening: Extruded semi-conductive compound

Insulation: XLPE

Insulation Screening: Extruded semi-conductive compound,

Screen: Copper wires and copper helix, swelling powder

Laminated Core Sheath: Aluminium tape bonded to overlaying PE sheath

Fillers: Polypropylene filler

Fiber-Optic Element: Fiber optic cable,

Separator: Binder tapes

Bedding Layer: Polypropylene strings,

Armour: Galvanized steel wires.,

Serving: Hessian tapes, bituminous compound, polypropylene strings

Standard: ASTM, IEC, BS, DIN etc

Application:

1.submarine communications cable is a cable laid on the sea bed between land-based stations to carry telecommunication signals across stretches of ocean, which can suit for seabed and sea area ambient condition, ocean physics characteristic and requirements of laying underwater, with waterproof, anti-corrosion, good machine performance and so on.

2.Modern cables are typically about 25 millimetres (0.98 in) in diameter and weigh around 1.4 kilograms per metre (0.4 lb/ft) for the deep-sea sections which comprise the majority of the run, although larger and heavier cables are used for shallow-water sections near shore.

Submarine Cable Technical Date:

| Type of fiber | B1.1 | B4 | |||

| Wavelength(nm) | 1310 | 1550 | 1550 | ||

| Attenuation coefficient(max)(dB/km) | 0.36 | 0.22 | 0.22 | ||

| PMD | M | 20 | 20 | ||

| Q | 0.01% | 0.01% | |||

| PMDQ (max) | 0.5ps/km1/2 | 0.5ps/km1/2 | |||

| Zero-dispersion Wavelength(nm) | 1300~1324 | —— | |||

| Zero-dispersion Slope (max) ps/(nm2·km) | 0.093 | —— | |||

| Absolute value of Chromatic Dispersion ps/(nm·km) | 1288~1339nm | 3.5 | —— | ||

| 1271~1360nm | 5.3 | —— | |||

| 1550nm | 18 | —— | |||

| 1530~1565nm | —— | 0.1~10.0 | |||

| Dmax-Dmin 1530~1565nm | —— | 5 | |||

| cut-off wavelength lcc(nm) | ≤1260 | ≤14 | |||

3.The submarine cables made by our company is armoured with high-tensile steel wire and used with technologies of water-proof and corrosion-proof to ensure the superior properties, test are performed in accordance with IEC60055, IEC60502 and methods recommended.