H07RN-F Cable Heavy Standard Construction

Conductor: Class 5 flexible plain copper to BS EN 60228:2005(previously BS6360)

Insulation: EPR(Ethylene Propylene Rubber) Type E14 to BS7655, oil-resistant, flame-retardant.

Sheath: PCP(Polychioroprene) Type EM3 to BS7655

Sheath Color: Black

Voltage: 450/750V

Temperature Rating: conductor operation temperature -30°C to +60°C(85°C max)

Minimum Bending Radius: Up to 25mm2:6xoverall diameter;

Above to 25mm2:8xoverall diameter

Standards: BS7919 CENELEC HD22 4S4

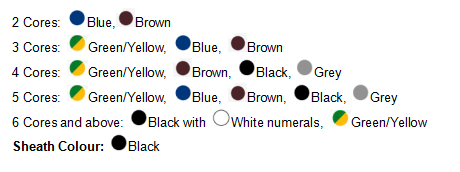

Core identification:

H07RN-F Rubber Cable Size Parameter:

| Number of cores and mm² per conductor | Outer diameter [mm] | Copper index (kg/km) | Weight (kg/km) |

| 1 X 1.5 | 5.7 – 6.5 | 14.4 | 59 |

| 1 X 2.5 | 6.3 – 7.2 | 24 | 72 |

| 1 X 4.0 | 7.2 – 8.1 | 38.4 | 99 |

| 1 X 6.0 | 7.9 – 8.8 | 57.6 | 130 |

| 1 X 10.0 | 9.5 – 10.7 | 96 | 230 |

| 1 X 16.0 | 10.8 – 12.0 | 153.6 | 320 |

| 1 X 25.0 | 12.7 – 14.0 | 240 | 450 |

| 1 X 35.0 | 14.3 – 15.9 | 336 | 605 |

| 1 X 50.0 | 16.5 – 18.2 | 480 | 825 |

| 1 X 70.0 | 18.6 – 20.5 | 672 | 1090 |

| 1 X 95.0 | 20.8 – 22.9 | 912 | 1405 |

| 1 X 120.0 | 22.8 – 25.1 | 1152 | 1745 |

| 1 X 150.0 | 25.2 – 27.6 | 1440 | 1887 |

| 1 X 185.0 | 27.6 – 30.2 | 1776 | 2274 |

| 1 X 240.0 | 30.6 – 33.5 | 2304 | 2955 |

| 3 G 1.0 | 8.3 – 9.6 | 28.8 | 130 |

| 2 X 1.5 | 8.5 – 9.9 | 28.8 | 135 |

| 3 G 1.5 | 9.2 – 10.7 | 43.2 | 165 |

| 4 G 1.5 | 10.2 – 11.7 | 57.6 | 200 |

| 5 G 1.5 | 11.2 – 12.8 | 72 | 240 |

| 7 G 1.5 | 14.7 – 16.5 | 100.8 | 385 |

| 12 G 1.5 | 17.6 – 19.8 | 172.8 | 516 |

| 19 G 1.5 | 20.7 – 26.3 | 273.6 | 800 |

| 24 G 1.5 | 24.3 – 27.0 | 345.6 | 882 |

| 2 X 2.5 | 10.2 – 11.7 | 48 | 195 |

| 3 G 2.5 | 10.9 – 12.5 | 72 | 235 |

| 4 G 2.5 | 12.1 – 13.8 | 96 | 290 |

| 5 G 2.5 | 13.3 – 15.1 | 120 | 294 |

| 7 G 2.5 | 17.1 – 19.3 | 168 | 520 |

| 12 G 2.5 | 20.6 – 23.1 | 288 | 810 |

| 19 G 2.5 | 25.5 – 31 | 456 | 1200 |

| 24 G 2.5 | 28.8 – 31.9 | 576 | 1298 |

| 2 X 4.0 | 11.8 – 13.4 | 76.8 | 270 |

| 3 G 4.0 | 12.7 – 14.4 | 115.2 | 320 |

| 4 G 4.0 | 14.0 – 15.9 | 153.6 | 395 |

| 5 G 4.0 | 15.6 – 17.6 | 192 | 485 |

| 7 G 4.0 | 20.1 – 22.4 | 268.8 | 681 |

| 3 G 6.0 | 14.1 – 15.9 | 172.8 | 360 |

| 4 G 6.0 | 15.7 – 17.7 | 230.4 | 475 |

| 5 G 6.0 | 17.5 – 19.6 | 288 | 760 |

| 3 G 10.0 | 19.1 – 21.3 | 288 | 880 |

| 4 G 10.0 | 20.9 – 23.3 | 384 | 1060 |

| 5 G 10.0 | 22.9 – 25.6 | 480 | 1300 |

| 3 G 16.0 | 21.8 – 24.3 | 460.8 | 1090 |

| 4 G 16.0 | 23.8 – 26.4 | 614.4 | 1345 |

| 5 G 16.0 | 26.4 – 29.2 | 768 | 1680 |

| 4 G 25.0 | 28.9 – 32.1 | 960 | 1995 |

| 5 G 25.0 | 32.0 – 35.4 | 1200 | 2470 |

| 3 G 35.0 | 29.3 – 32.5 | 1008 | 1910 |

| 4 G 35.0 | 32.5 – 36.0 | 1344 | 2645 |

| 5 G 35.0 | 35.7 – 39.5 | 1680 | 2810 |

| 4 G 50.0 | 37.7 – 41.5 | 1920 | 3635 |

| 5 G 50.0 | 41.8 – 46.6 | 2400 | 4050 |

| 4 G 70.0 | 42.7 – 47.1 | 2688 | 4830 |

| 4 G 95.0 | 48.4 – 53.2 | 3648 | 6320 |

| 4 G 120.0 | 53.0 – 57.5 | 4608 | 6830 |

| 4 G 150.0 | 58.0 – 63.6 | 5760 | 8320 |

| 4 G 185.0 | 64.0 – 69.7 | 7104 | 9800 |

| 4 G 240.0 | 72.0 – 79.2 | 9216 | 12800 |

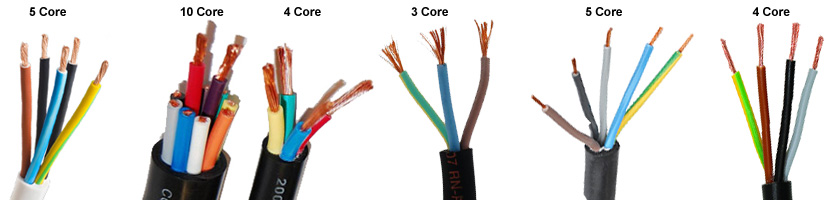

Application:

These cables are designed to provide high flexibility and have the capacity to withstand weather oils/greases, mechanical and thermal stresses. Applications include handling equipment, mobile power supplies, work sites, stage and audio visual equipment, port areas and dams. Also for use in drainage and water treatment, cold environments and severe industrial Environments.